Aac Masa

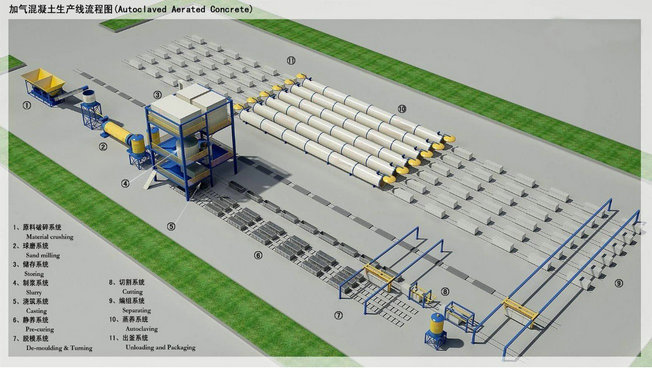

Masa s aerated concrete installations are proven advanced technology processes designed according to customers specific requirements.

Aac masa. Right from the start of this project the possibility for an extension had been considered in the plant layout so that. Masa s aerated concrete installations are proven advanced technology processes designed according to customers specific requirements. Since march 2012 the plant works with a daily capacity of 1400 m. Plants for the production of all types of concrete blocks concrete slabs aerated concrete aac kerbstones and sand lime bricks.

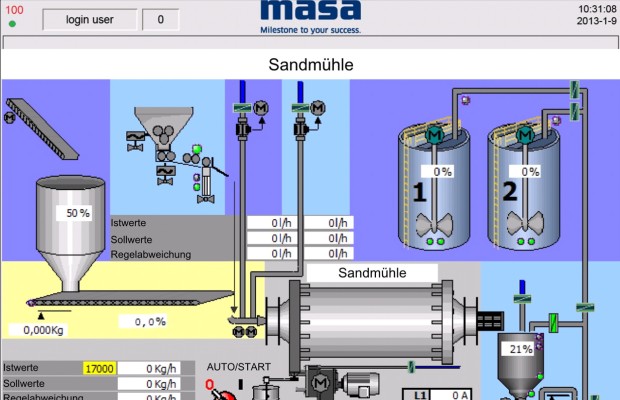

The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates the control of the fermentation process and the control of each production step. Masa trainees on tour visit to a sand lime and aac making factory 23 oct 2020 innovation germany film about masa gmbh on welt de 28 aug 2020 world s first masa xl r in operation decopave starts promising concrete block production 14 aug 2020. The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates the control of the fermentation process and the control of each production step. Masa s aerated concrete installations are proven advanced technology processes designed according to customers specific requirements.

Masa s aerated concrete installations are proven advanced technology processes designed according to customers specific requirements. The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates the control of the fermentation process and the control of each production step. The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates the control of the fermentation process and the control of each production step. This approach allows complete solutions to ensure highly.

The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates the control of the fermentation process and the control of each production step.

_Bildergalerie.jpg)

_Bildergalerie.jpg)

_Bildergalerie.jpg)

_Bildergalerie.jpg)

_Bildergalerie.jpg)

_Bildergalerie.jpg)